media coverage

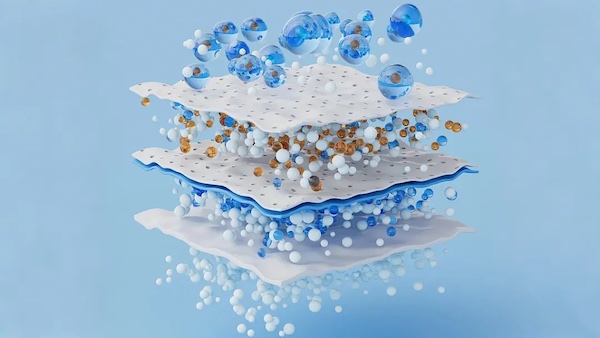

An electronic factory's reverse osmosis system ran for less than half a year, the amount of water produced dropped by 30%, electricity consumption increased dramatically and changing the membrane cost more than 500,000 yuan each year. Engineers disassemble the membrane module to see that the surface has been embedded with thick biofilm and salt scale, similar to a coating of 'cement' .

Are you familiar with this scene?

According to statistics, over 90 percent of reverse osmosis system failures are caused by the incorrect choice of water treatment chemicals! Today, we will demonstrate how to build a reverse osmosis membrane system to extend its service life through experience and the idea of the agent in two dimensions.

Part I : The three key factors affecting the life of the membrane

1) Microbial contamination - membrane 'immunodeficiency'

- Microorganisms on the surface of the membrane to form a mucus-like biofilm, resulting in:

- Water flux decline of 15~20% (biofilm blocking pore).

- Frequent chemical cleaning (acid and alkali detergent to accelerate the aging of membrane materials).

2) Inorganic salt scaling - membrane 'atherosclerosis'

Key thresholds:

- LSI >1.5, the risk of scaling soars by 80% (Langelier saturation index)

- 1 mm thick scale can lead to an increase in system energy consumption by 15% (pumping demand increases)

Calcium and magnesium scales are deposited like plaques on the walls of the blood vessels, which gradually block the membrane poreways, causing:

- Decrease in permeability, resulting in: → 15~20% reduction in water throughput, and the production of water. Decrease in water permeability and flux.

- Irreversible physical damage to the membrane element.

3) Chemical oxidation damage - membrane 'chronic disease'

Residual chlorine in the water (e.g. sodium hypochlorite) continues to attack the cross linked structure of the polyamide membrane, resulting in:

-Membrane desalination rate decreases by 5~8% per year.

-Membrane brittleness and rupture risk increased by 3 times.

-Initial performance degradation is not obvious, but the cumulative damage ultimately leads to membrane element failure, especially when the residual chlorine of the RO influent is high, it will rapidly oxidize the membrane. When the residual chlorine in RO feed water is high, the membrane will be oxidised rapidly and the desalination rate will drop rapidly and irreversibly.

Part II: Industry Common Misconceptions

Myth 1: As long as the regular cleaning can solve the problem.

Truth: Each cleaning caused irreversible damage to the membrane.

Data: Frequent cleaning of the membrane life is 40% shorter than that of the scientific conservation.

Myth 2: Scale inhibitors are similar, choose the cheap on the line.

Experimental proof: low-quality agents scale inhibition rate of less than 85%;

high-quality agents scale inhibition rate of 97.5%.

Myth 3: Wait for the membrane to fail before looking for pharmaceutical problems.

Cost calculation: preventive pharmaceutical input vs membrane replacement costs = 1:7

Part III: Polymer Solution

Dual-action scale inhibitor: Adopting molecular directed chelating technology, specifically binding Ca2?/Mg2? (binding constant Kf>101?),Inhibiting crystal nucleus growth.

Bacteriostatic antioxidant:

-Isothia or organobromine complex (at 0.5ppm), biofilm formation inhibition rate ≥90%

-Synchronous scavenging of hydroxyl radicals (-OH), redox potential maintenance <200mV.

pH adaptive formulation:Wide range pH stability (5.0~8.0), protective film material.

Part IV: Empirical Cases

A well-known lithium battery manufacturer

Problem:RO membrane is prone to fouling and clogging, resulting in a drop in water production and an increase in operating pressure, which seriously affects the stability of the system and the life of the membrane.

Measures:Switch to TRISPE® seriesScaleInhibitor.

Effect:

-Extend the cleaning cycle from 1 month/time to 3~4 months/time, 3 times longer.

-Increase the system recovery rate from 70 to 75%.

-Extend the membrane life from 1.5~2 years to 3~4 years, reduce the cost of membrane replacement.

Part V: Guidelines for action

5 Golden Guidelines for Pharmaceutical Selection:

- Ingredient compliance review: Provide complete MSDS, focusing on verification of active component content, impurity indicators, etc.

- Performance certification requirements: ScaleInhibition performance, bactericidal performance, etc., provide third-party performance certification.

- System suitability verification: Membrane compatibility test, material compatibility, etc.

- Technical service qualification: ‘Industrial Water Treatment Engineer’ professional qualification, the ability to issue programmes, etc.

- Intelligent control requirements: dosing equipment, dosage calculation software, etc.